We have a solution for you.

You want to reduce the number of repeat repairs on your customer's vehicles. You want your technicians to work with the most sophisticated, high-tech equipment available. You want to provide your customers with a vehicle whose systems have been thoroughly tested. Whatever field you are in, you strive for perfection — and so do we. Our team of highly qualified software engineers has extensive experience in complete system development. We have considerable knowledge of and experience in the automotive industry. We have a complete line of sophisticated communication products, including our vehicle interface adapters with networking capabilities. The result: a fully proven, technologically advanced diagnostic/test solution created just for you.

You want proof? We have it.

Vehicle Diagnostic System

The Service Bay Diagnostic System® (SBDS®) is an advanced

computerized information and diagnostic system used

to provide guided automotive repair technology. This

system was designed and developed by a team of suppliers

to help Ford Motor Company reduce its vehicle warranty

repair costs and help its dealerships fix their customers

cars "right the first time." EnGenius worked closely

with Hewlett Packard, the hardware supplier, and contributed

greatly to the development and release of the SBDS product

to Ford Motor Company dealerships. EnGenius was responsible

for the management, development, and release of all

SBDS diagnostic software.

The Service Bay Diagnostic System® (SBDS®) is an advanced

computerized information and diagnostic system used

to provide guided automotive repair technology. This

system was designed and developed by a team of suppliers

to help Ford Motor Company reduce its vehicle warranty

repair costs and help its dealerships fix their customers

cars "right the first time." EnGenius worked closely

with Hewlett Packard, the hardware supplier, and contributed

greatly to the development and release of the SBDS product

to Ford Motor Company dealerships. EnGenius was responsible

for the management, development, and release of all

SBDS diagnostic software.

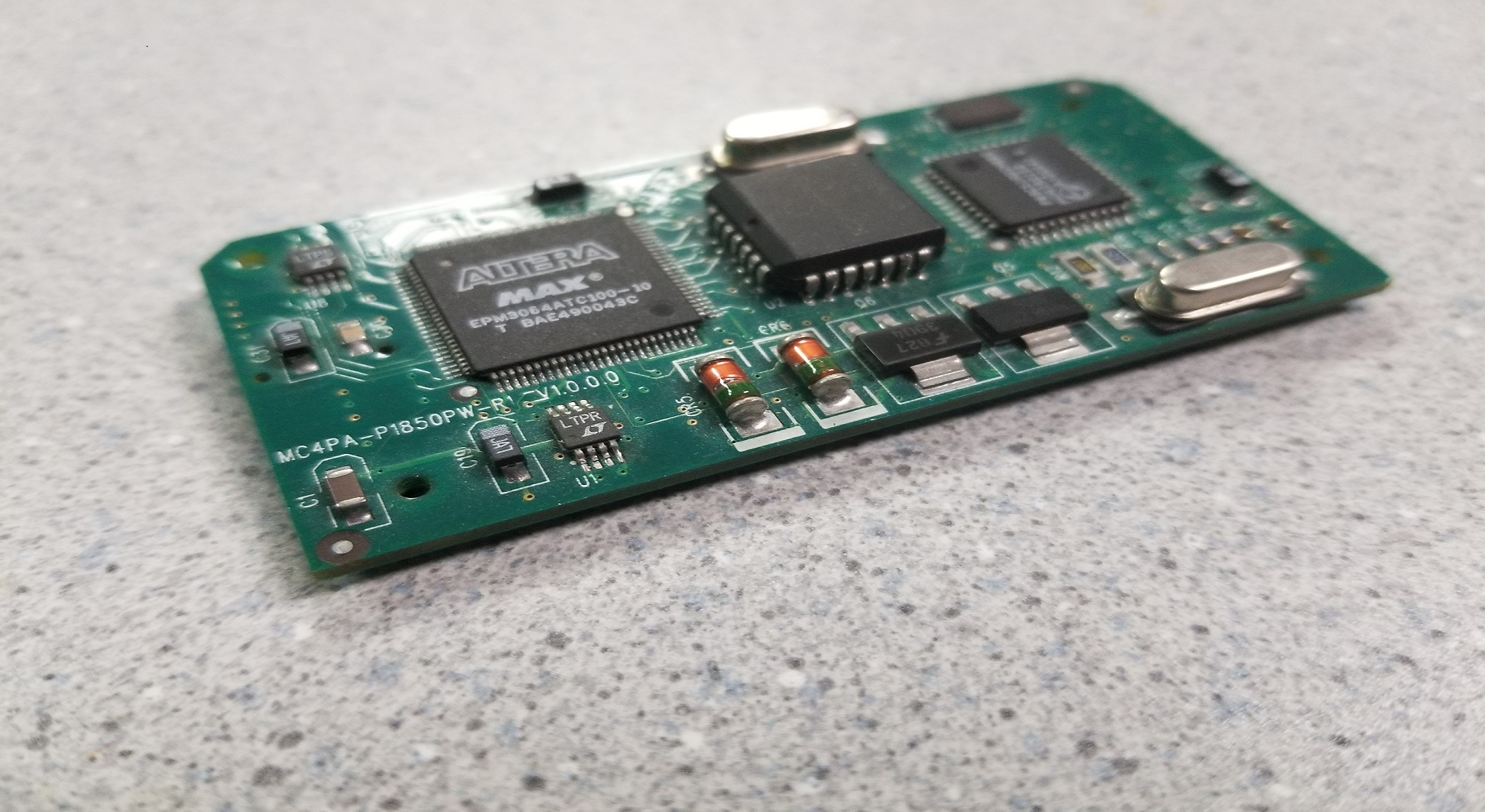

Vehicle Assembly Test System

The Vehicle Assembly Test System was an automated computer-based

diagnostic and test system installed in over 25 vehicle

assembly plants throughout the world. The system supported:

data and calibration engineering, remote monitoring,

remote access, web-based reporting, and network diagnostics.

The system included peripherals such as barcode scanners,

overhead marquis displays, and transponder readers.

Vehicle modules could be configured using a hand-held

PC-based computer with an RF spread spectrum radio transceiver

allowing the system to be mobile within the assembly

process and adapt to fluid assembly related issues.

Major benefits of the system include detecting assembly

faults, identifying component failures, complying with

state and federal regulations, increasing quality, decreasing

warranty costs, and decreasing turnaround time for component

engineering. In addition, the Vehicle Assembly Test

System could reprogram vehicle embedded controllers

reducing inventory and cost using RFDC and the MultiCom

vehicle network interface product family.

The Vehicle Assembly Test System was an automated computer-based

diagnostic and test system installed in over 25 vehicle

assembly plants throughout the world. The system supported:

data and calibration engineering, remote monitoring,

remote access, web-based reporting, and network diagnostics.

The system included peripherals such as barcode scanners,

overhead marquis displays, and transponder readers.

Vehicle modules could be configured using a hand-held

PC-based computer with an RF spread spectrum radio transceiver

allowing the system to be mobile within the assembly

process and adapt to fluid assembly related issues.

Major benefits of the system include detecting assembly

faults, identifying component failures, complying with

state and federal regulations, increasing quality, decreasing

warranty costs, and decreasing turnaround time for component

engineering. In addition, the Vehicle Assembly Test

System could reprogram vehicle embedded controllers

reducing inventory and cost using RFDC and the MultiCom

vehicle network interface product family.

Vehicle Calibration System: CALVIN

CALVIN was jointly developed by Ford Motor Company,

Texas Micro, Inc., and EnGenius to perform calibrations

on engine controller software. The task of calibrating

engine control software involves changing data used

by the algorithms that execute in engine controllers

to provide optimal performance for a vehicle/powertrain.

By investigating and setting literally thousands of

variables in the engine control software, the calibrators

find the proper balance between performance, fuel economy,

and emissions. Calibrators also verify the performance

of the vehicle in all operating environments, from extreme

heat to extreme cold and high altitude.

CALVIN was jointly developed by Ford Motor Company,

Texas Micro, Inc., and EnGenius to perform calibrations

on engine controller software. The task of calibrating

engine control software involves changing data used

by the algorithms that execute in engine controllers

to provide optimal performance for a vehicle/powertrain.

By investigating and setting literally thousands of

variables in the engine control software, the calibrators

find the proper balance between performance, fuel economy,

and emissions. Calibrators also verify the performance

of the vehicle in all operating environments, from extreme

heat to extreme cold and high altitude.